Hey there, friends! Let me tell you something fascinating about temporary replacement 3 full solutions that could change the way you handle unexpected situations. Whether you're in the world of business, manufacturing, or even personal projects, understanding how to implement temporary replacements effectively can save you tons of time, money, and stress. Trust me, I've seen countless scenarios where businesses thrive—or fail—based on how well they handle these transitions. So, buckle up and let's dive deep into this crucial topic!

Now, you might be wondering, "What exactly does 'temporary replacement 3 full' mean?" Well, it's not just about filling in gaps—it's about ensuring that every component, system, or process keeps running smoothly without losing productivity. Think of it like a backup plan that's so solid, it feels almost permanent. This concept has become increasingly important in today's fast-paced world, where downtime can cost companies millions.

In this article, we'll explore everything you need to know about temporary replacements, from the basics to advanced strategies. We'll also discuss real-world examples, expert tips, and actionable advice to help you implement these solutions with confidence. So whether you're a business owner, manager, or simply someone curious about optimizing processes, this guide is for you. Let's get started!

Read also:Married Steve Dulcich The Love Story Everyones Talking About

Table of Contents

- Introduction to Temporary Replacement 3 Full

- Benefits of Temporary Replacement Solutions

- Types of Temporary Replacement Systems

- How to Implement Temporary Replacement 3 Full

- Cost Analysis and Budgeting

- Common Challenges and How to Overcome Them

- Real-World Examples of Successful Implementation

- Maintenance and Long-Term Planning

- The Future of Temporary Replacement Technologies

- Conclusion: Why Temporary Replacement Matters

Introduction to Temporary Replacement 3 Full

Temporary replacement 3 full solutions are designed to bridge gaps in operations, ensuring continuity without compromising quality. Imagine a manufacturing plant where a critical machine breaks down. Instead of halting production entirely, a temporary replacement can keep things moving while the main equipment is repaired or replaced. It's like having a spare tire in your car—essential when you least expect it.

In today's competitive market, businesses cannot afford downtime. That's why understanding the nuances of temporary replacement strategies is vital. From choosing the right technology to ensuring seamless integration, every step matters. And let's not forget, the "3 full" aspect refers to comprehensive, full-scale solutions that cover all aspects of a process or system.

Why Temporary Replacement is Crucial

Here are a few reasons why temporary replacement is more important than ever:

- Minimizes operational disruptions

- Reduces financial losses

- Improves customer satisfaction

- Enhances overall efficiency

Benefits of Temporary Replacement Solutions

When it comes to temporary replacement 3 full, the benefits are immense. Businesses that adopt these solutions often experience significant improvements in productivity, cost management, and customer relations. Let's break it down:

First off, temporary replacements allow companies to maintain their output levels, even during unexpected events. This consistency is crucial in industries where demand is high and competition fierce. Additionally, these solutions provide flexibility, enabling organizations to adapt quickly to changing circumstances.

Key Advantages

- Quick deployment

- Customizable options

- Scalability for growing needs

- Reduced risk of project delays

Types of Temporary Replacement Systems

Not all temporary replacement systems are created equal. Depending on your industry and specific requirements, you may need to choose between different types of solutions. Here's a quick rundown:

Read also:How To Maximize Fuel Rewards Your Ultimate Guide To Saving Big On Gas

1. Equipment-Based Replacements

These involve using backup machines or tools to fill in for primary equipment. Ideal for manufacturing and construction industries.

2. Software and IT Solutions

In the digital realm, temporary software replacements can ensure business continuity during system upgrades or failures.

3. Personnel Replacements

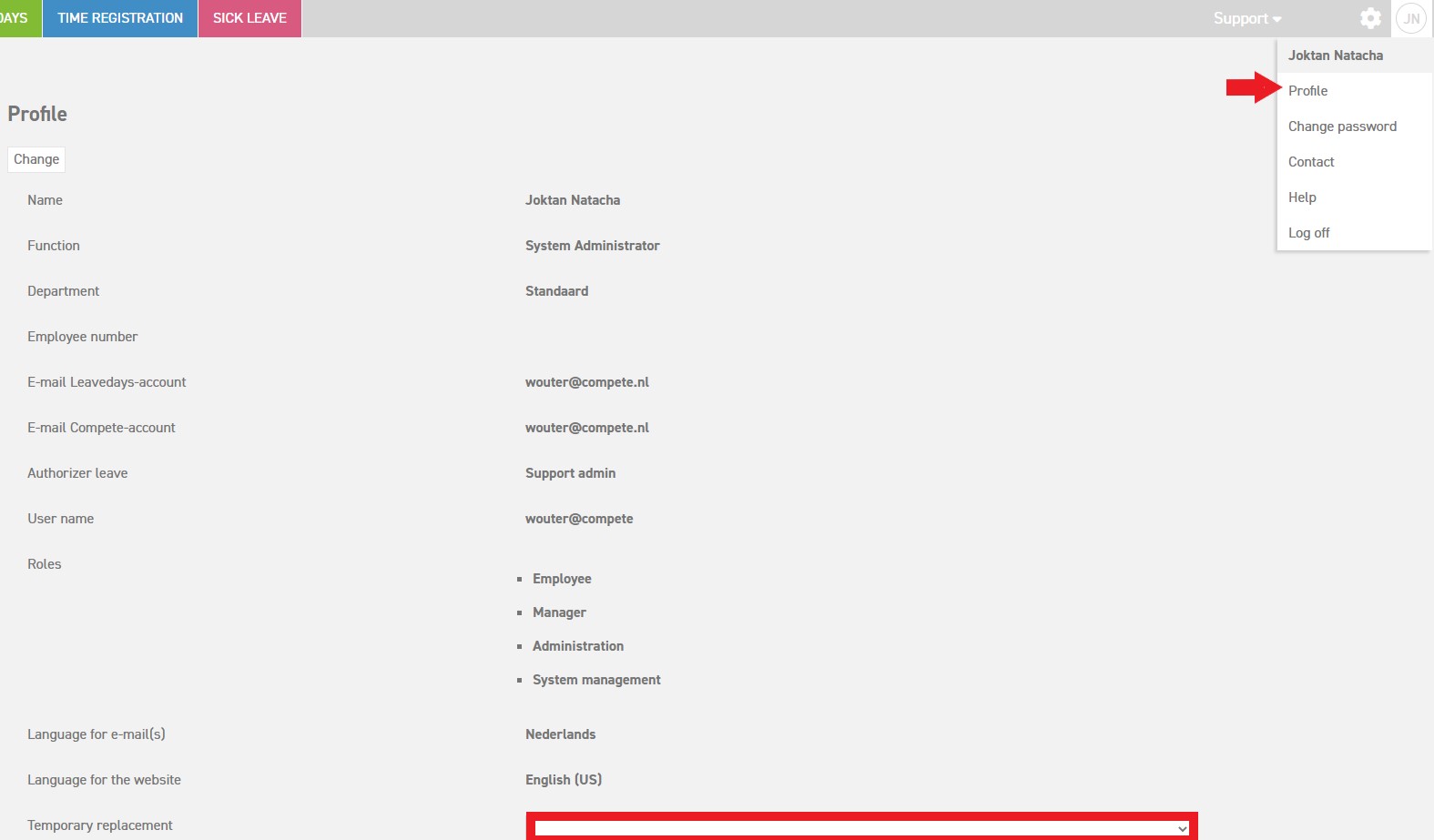

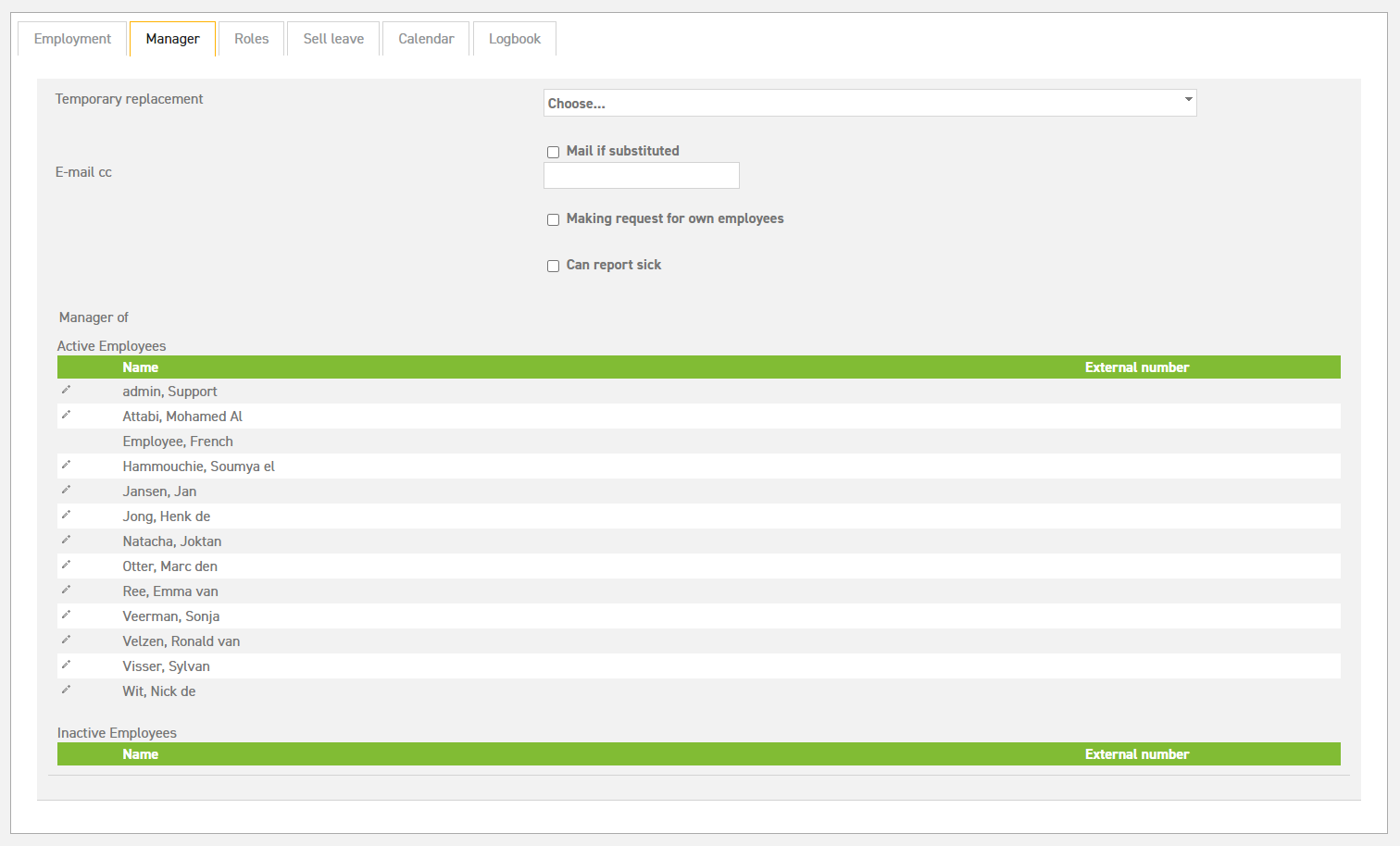

When key employees are unavailable, temporary staffing solutions can keep operations running smoothly.

How to Implement Temporary Replacement 3 Full

Implementing a temporary replacement 3 full strategy requires careful planning and execution. Here are the steps to follow:

Start by identifying potential risks and areas where temporary solutions could be beneficial. Next, evaluate available options and select the ones that best fit your needs. Finally, train your team to ensure smooth transitions when these solutions are activated.

Step-by-Step Guide

- Assess risks and vulnerabilities

- Research suitable replacement options

- Develop an implementation plan

- Test the system before full deployment

Cost Analysis and Budgeting

One of the biggest concerns businesses have about temporary replacement solutions is cost. However, the investment is often worth it when you consider the potential savings from avoiding downtime. According to a report by McKinsey, companies that implement effective temporary replacement strategies see an average 20% increase in operational efficiency.

When budgeting for these solutions, consider both upfront costs and long-term savings. Factor in variables like equipment rental fees, software licenses, and staffing expenses. Remember, the goal is to find a balance between affordability and effectiveness.

Common Challenges and How to Overcome Them

While temporary replacement 3 full solutions offer numerous advantages, they do come with challenges. Some common issues include compatibility problems, integration difficulties, and resistance from team members. Here's how to tackle them:

- Ensure all components are compatible before deployment

- Provide comprehensive training for your team

- Regularly update and maintain replacement systems

Real-World Examples of Successful Implementation

Let's take a look at some real-world examples of businesses that have successfully implemented temporary replacement strategies:

Case Study 1: A major automotive manufacturer faced a sudden breakdown of its assembly line machinery. By deploying a temporary replacement system, they were able to resume production within hours, minimizing losses.

Case Study 2: An e-commerce platform experienced a server crash during peak shopping season. Their temporary IT solution ensured customers could still place orders without interruption.

Maintenance and Long-Term Planning

Once you've implemented a temporary replacement 3 full solution, it's essential to maintain it properly. Regular inspections, updates, and testing can prevent issues down the line. Additionally, long-term planning ensures that your temporary solutions remain relevant and effective as your business evolves.

The Future of Temporary Replacement Technologies

The world of temporary replacement is evolving rapidly, thanks to advancements in technology. From AI-driven solutions to modular systems, the possibilities are endless. As industries continue to embrace digital transformation, we can expect even more innovative approaches to temporary replacement in the future.

Conclusion: Why Temporary Replacement Matters

So there you have it, friends! Temporary replacement 3 full solutions are not just a contingency plan—they're a strategic asset that can elevate your business to new heights. By understanding the benefits, types, and implementation strategies, you can ensure your organization is prepared for whatever challenges come its way.

Now, here's where you come in. Take a moment to reflect on how temporary replacement could impact your business. Share your thoughts in the comments below or explore other articles on our site for more insights. Remember, knowledge is power, and staying ahead of the curve is the key to success!

Thanks for reading, and keep shining!